Pallet Conveyor

Conveyor System | Undercoating overhead conveyors

What is our conveyor systems?

The conveyor system in the painting factory is an automatic transportation system that is involved in the entire process from receiving the car body from the welding factory, passing through the painting process, and handing over the car body to the assembly factory. Taikisha supports various transportation systems, from the hanger / trolley method that has been used in Japan for a long time to the skid method that is mainly used in Europe. In addition, it can be used not only for automobile bodies but also for painting systems for plastic parts.

What is undercoating overhead conveyors?

Overhead conveyor is used in the undercoat process.

- Want to lift productivity

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

- Want to improve labor environments and achieve automation

Overview

This conveyor is an overhead pallet conveyor applied in the undercoat process. It is a friction type transport and is a tact type (continuous type is also possible). It can also be used in robot processes.

Compared to the conventional hanger type, it is supported by a shorter length than the arm, and the pallet is mounted on the left and right rails, so there is less shaking and stability is higher.

Features

-

Both high-speed movement or low-speed continuous movement

High-speed movement is possible due to the friction method, and low-speed continuous movement is also possible.

-

High energy efficiency

The friction system can increase energy efficiency by operating only when the hanger is detected.

-

Reduction of installation space

The line to return empty pallets is placed above the machine, allowing a smaller installation space

-

Reduced noise of operation

Adopting a friction system can reduce the noise of operation.

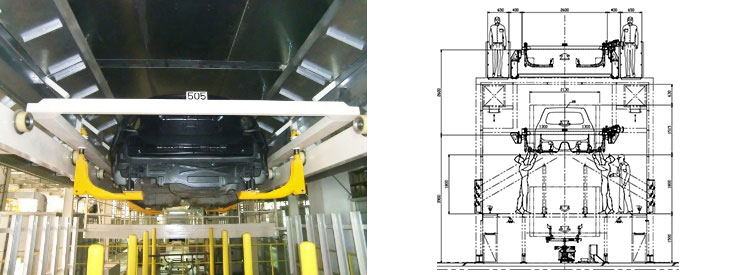

Installation Illustration

Inside at the working area

Inside at the working area

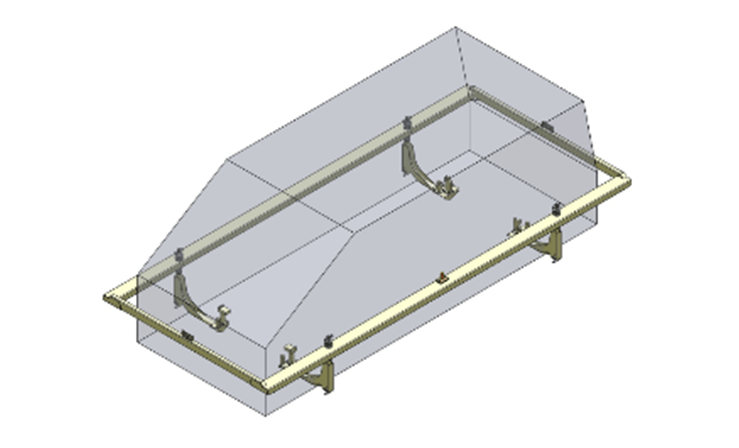

Pallet over view

Pallet over view

Body Transfer and up/down lifter

Body Transfer and up/down lifter