Paint Recovery System

Electrodepositing System | Technologies for Reducing the Volume of Wastewater and Materials Used

What is Electrodepositing System?

In the electrodeposition process an electrodeposition coat with excellent anti-corrosion properties forms on the chemical conversion coating. The electrodeposition coat plays an important role in protecting metal from rust and corrosion. Electrodepositing system provides technology to effectively form coatings that meet or exceed the standard set values on every inch of the object being painted.

What is technologies for reducing the volume of wastewater and materials used?

The electrodeposition water rinse process uses water filtered through UF and RO membranes to reduce the amount of flesh water needed to wash the object being painted, while recovering excess paint on the object to the electrodeposition tank. Taikisha examines the most economic membrane filtration technology and offers it to you.

- Want to heighten equipment efficiency and paint quality

Overview

Our rinse systems achieve a high paint recovery rate with UF or RO. They are designed to reduce waste water that is discharged from electro-deposition systems and contribute to environmental preservation.

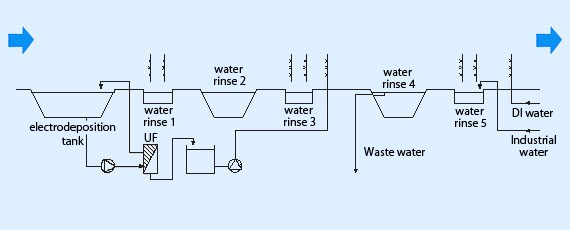

Water rinse after electrodeposition in 1980s

UF rinse in three stages, industrial water rinse in two stages, full-dip stage

Paint recovery rate: 96%; waste water: 200 to 300 L/unit

Paint recovery rate: 96%; waste water: 200 to 300 L/unit

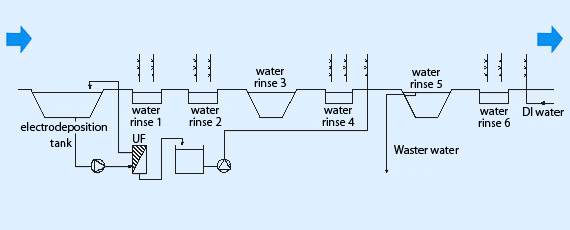

Water rinse after electrodeposition in 1990s

UF rinse in four stage, pure water rinse in two stages

Paint recovery rate: 97%; waste water: 120 L/unit

Paint recovery rate: 97%; waste water: 120 L/unit

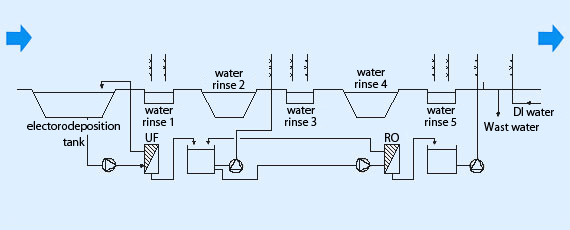

Water rinse after electrodeposition with RO

UF / RO rinse in five stages

Paint recovery rate: 99%; waste water: 30 to 40 L/unit

Paint recovery rate: 99%; waste water: 30 to 40 L/unit

-

*UF (Ultra Filter): Paint filtering devices with ultrafilter membrane

-

*RO (Reverse Osmosis): Paint filtering devices with reverse osmosis membrane

Features

UF systems have long been used in post-water rinse after electrodeposition to rinse off excess paint adhering to the object being coated, and to recover paint components.

In recent years, RO systems with higher filtration accuracy have been increasingly introduced to improve cleaning of painted objects and to reduce the volume of de-ionized water required for washing in later stages. They also improve the recovery rate of electrodeposition paint components and reduce paint consumption, helping to lower running costs.

At the same time, RO systems have higher initial costs and may have issues in terms of stability, so Taikisha will suggest the best system to match clients' needs.