Chemical Contamination Prevention System

Industrial Clean Room (ICR) Technology | Countermeasures Against Molecular Contamination Technology

What is Industrial Clean Room (ICR) technology?

Low-Cost, Low-Energy component techniques or total engineering technologies that electronics industry requires; air cleanliness, high-precision temperature, humidity and airflow environments, and countermeasures against molecular contamination or microscopic vibration.

What is molecular contamination control technology?

Comprehensive countermeasures for molecular contaminants to be removed from production environments in ICR, such as prevention of external incursion, internal generation from building or facility materials, and so as rapid removal of generated pollutants.

- Want to eliminate harmful substances/viruses

- Want to lift productivity

Overview

Based on our vast expertise, unique technologies, and proprietary databases, we provide AMC-proof cleanrooms that are fit just for your requirements.

Our design and construction technologies allow us to select equipment and materials with few chemical contaminants to meet our customers' needs, and to quickly remove chemical contamination occurred during construction work.

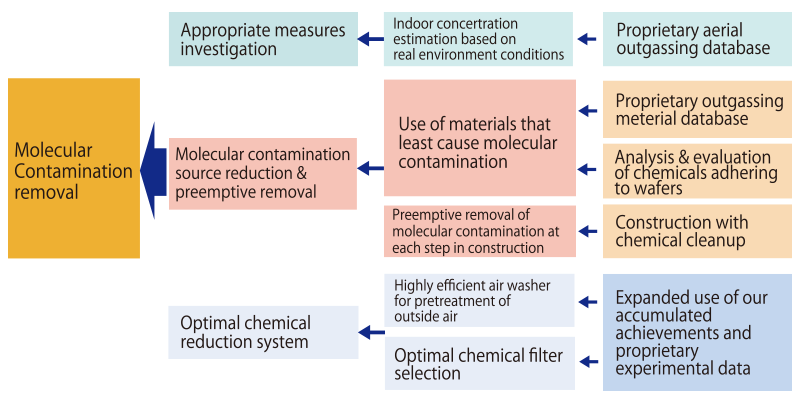

Our Concept of Chemical Molecular Contamination Countermeasures

Features

-

High-precision analysis of airborne chemical components for cleanrooms

To achieve a highly precise trace analysis of airborne chemical components in a completed cleanroom, it is necessary to minimize chemical contaminations due to human sampling intervention. To address this challenge, we have developed a high-precision analytical system for airborne chemical components, which has been utilized to analyze airborne chemicals in a large number of cleanrooms. Our analytical system for airborne chemical components can analyze any cleanroom in the world.

Chemical Components Produced in Cleanrooms

The airborne chemical contamination sources in a cleanroom include the construction materials of the room, staff members in the room, and process gases and chemical solutions. The following table lists the chemical components stemming from sources such as cleanroom construction materials.

| Generation Source | Generated Substance |

|---|---|

| Outside air | NOx, SOx, Na, Cl, and Ca |

| Prefilter and medium-performance filter (Non-cloth / Non-glass) | P (Ester Phosphate as a Flame-resistant Material) |

| HEPA & ULPA (Glass fiber), and thermally insulated, sound-deadening material | B, DBP, siloxane, toluene, xylene, benzenes - Generating from a filter paper binder, hotmelt, and packing |

| Chemical filter | Acetic acid is generated by the reaction of PGMEA in a process solvent with the acidic function in a chemical filter for base component reduction |

| EPDM (Ethylene-propylene-diene Monomer) rubber packing | Paraffinic material |

| Resin coated metal plate (Cabinet of Air-conditioning Equipment, Coil fin, etc.) | Paraffin; In rare cases, large amounts of organic substances have been generated. |

| Soft resin sheet (Vinyl Chloride Curtains) | DBP, DOP, phenols, benzenes, and dozens of other substances |

| Wire coating material (Non-eco Cable) | Organic phosphorus, DOP (a plasticizer), and siloxane |

| Electric machinery | Siloxane, lacquer, and fats and oils for lubrication |

| Paint (Antistatic and Dustproof) | Various metallic ions, benzenes, and fats |

| Partition (Composite Board) | Ethanol, etc. (Verify the Temperature and Time of Baking) |

| Concrete | NH3 and Ca |

| Silicon caulking agent | Siloxane, aldehydes, benzenes, toluene, etc. |

| Antistatic material (Wall, Floor, and Cabinet of Manufacturing Equipment) | C, Na, NO2, Ca, Fe, K, Co, amines, sulfonic acid, etc. |

| Human | NH3, acetone, Na, and Cl |

| Shoes and cosmetics | Various organic substances |

| Steam for humidification | AMP (Added as Antiscales for Boilers) |