Clean Diffuser

Industrial Clean Room (ICR) Technology | Airflow Control Technology

What is Industrial Clean Room (ICR) technology?

Low-Cost, Low-Energy component techniques or total engineering technologies that electronics industry requires; air cleanliness, high-precision temperature, humidity and airflow environments, and countermeasures against molecular contamination or microscopic vibration.

What is airflow control technology?

Technology to equalize cleanliness, temperature, and humidity levels in clean rooms by controlling inlet airflow with distinctive diffusing mechanisms.

- Want to heighten equipment efficiency

Overview

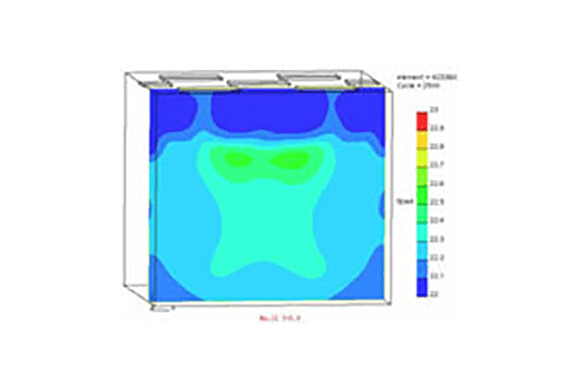

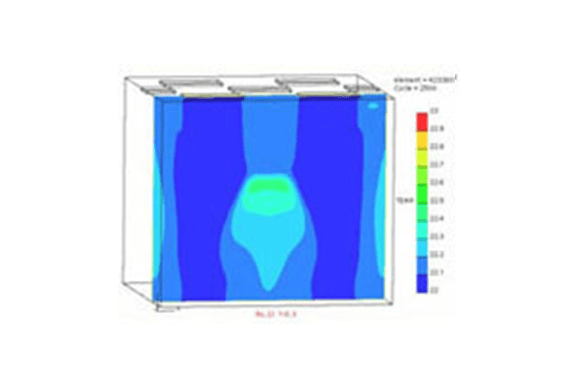

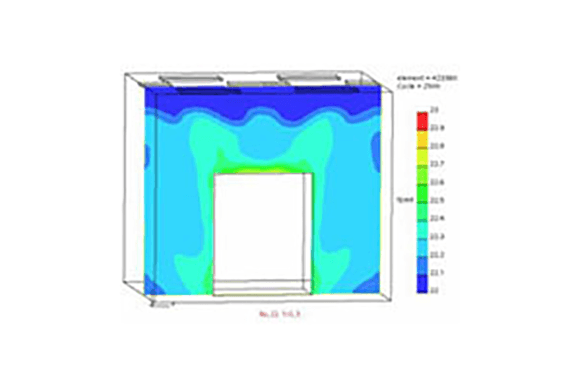

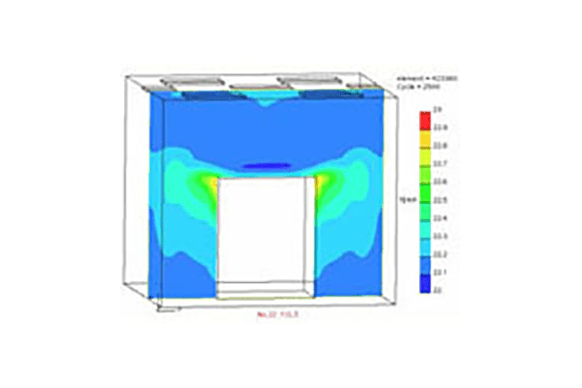

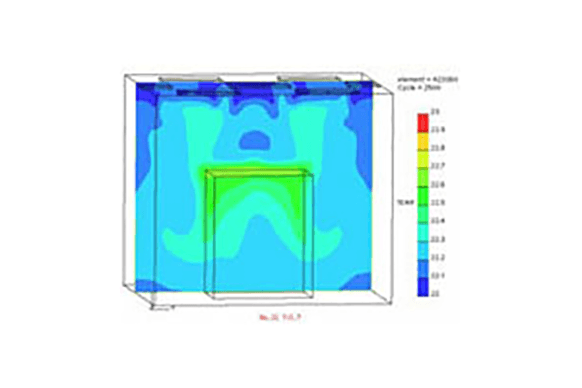

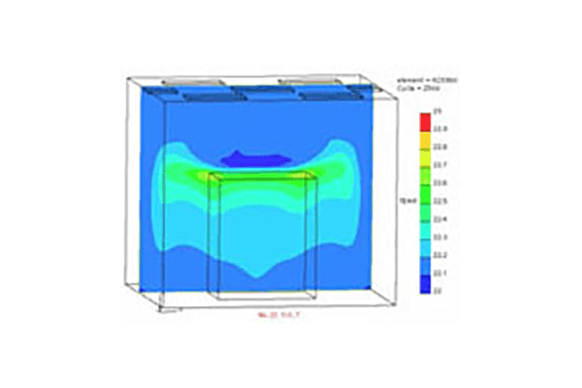

With the HEPA outlet located on a section of the ceiling, the cold air exits from the ceiling through the HEPA filter and is drawn down into under the floor, without dispersion. This causes the air in the cleanroom to partially stagnate, degrading the clean level and temperature distribution in the room.

Clean Diffuser creates optimal airflow with a minimized ventilation frequency by dispersing air exiting from the HEPA outlet, which has the effect of imitating airflow distributed from across the whole surface of the ceiling.

Features

-

Improving the air flow distribution of cleanrooms

By diffusing the airflow in the HEPA outlet, disparities in the airflow distribution between the lower part of the outlet and areas without the outlet can be eliminated, thereby improving the airflow and temperature distribution.

-

Energy-saving

Diffusive-type HEPA unit extends covering area, achieving air circulation reduction and so as the fan power.

Simulations/Field Trials

Airflow Simulations & Field Trials

Production Equipment: Front side

With Clean Diffuser

With Clean Diffuser

Without Clean Diffuser

Without Clean Diffuser

Production Equipment: Close Up

With Clean Diffuser

With Clean Diffuser

Without Clean Diffuser

Without Clean Diffuser

Production Equipment: Back side

With Clean Diffuser

With Clean Diffuser

Without Clean Diffuser

Without Clean Diffuser

Experiment Photos

With Clean Diffuser

With Clean Diffuser

Without Clean Diffuser

Without Clean Diffuser