Ultra-precise Temperature Control Chamber

Mini-Environment Technology

What is mini-environment technology?

Reduction of initial cost and operating cost for facility is enabled by minimizing spaces for higher clean levels. It also helps improving product quality and the yield.

- Want monitoring and control

Overview

This technology provides a precise temperature control at the level of ±5/1,000°C.

For manufacturing systems that require high-performance positioning, such as semiconductor and liquid crystal exposure systems, and precision measurement systems such as an electronic balance, Spacefine, with a direct expansion coil and hot gas reignition, provides energy-saving, low-cost, and high-precision solutions.

Specifications

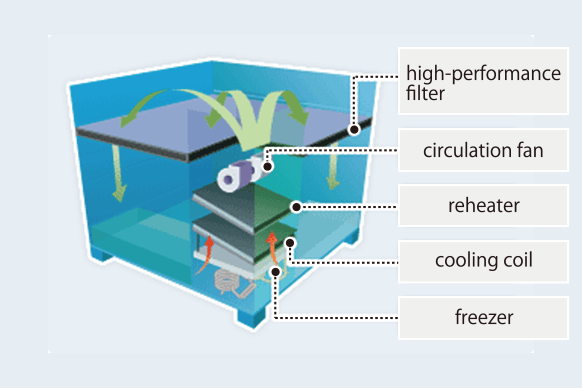

Structure of Ultra-precise Temperature Control Chamber (External View, Front & Main Chambers)

- Example installations of a direct expansion spacefine unit

- As a precision temperature control chamber installed in semiconductor and LCD factories.

- As other manufacturing or testing rooms that require precision temperature control.

- Adoption of a high-precision multi-loop controller

- Two point sensors cascade-control discharged air.

- Appropriate draft correction control based on installation environment.

- Cleanliness: 0.1µm, Class 1

- Low outgas materials reduce the concentration of chemicals in the chamber (ITRS-compliant).

- Special thermal insulation panels are used.