Energy-Saving HVAC Control

Paint booth | Energy-saving technology

What is paint booths?

Paint booths apply intermediate and top coat on the object being painted, forming designs, and coating to protect the undercoat from ultraviolet rays and the wind and rain. The large size of these machines emphasizes technologies to make them more compact and save energy with air conditioning controls.

What is energy-saving technology?

Paint booths consume the largest amount of energy among paint processes. Taikisha has developed and delivered many energy-saving HVAC control systems and other systems that save energy like exhaust air recycling ones.

- Want to reduce CO2 and enhance energy efficiency

Overview

HVAC for paint booths requires the highest energy consumption among paint facilities.

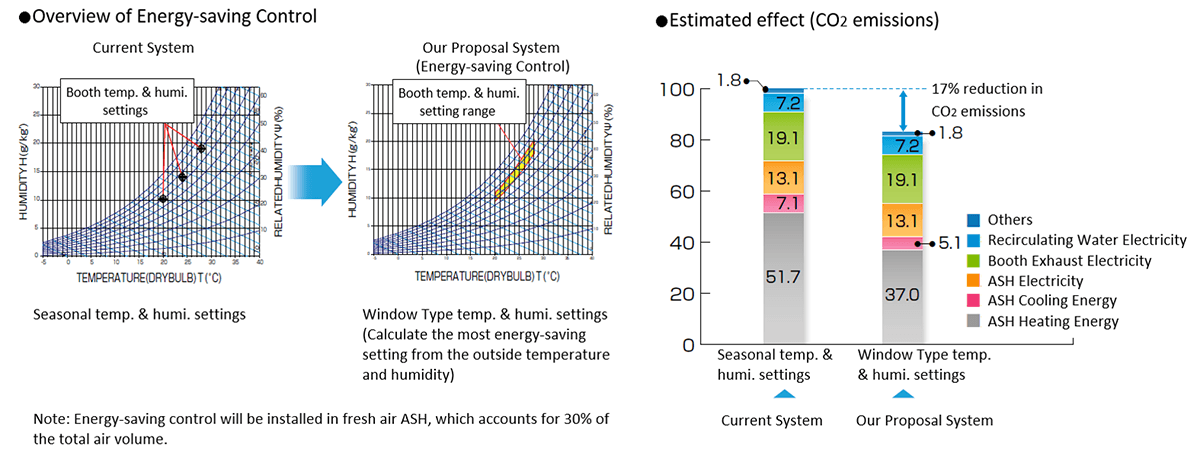

Our energy-saving HVAC system automatically determines an optimal control point in accordance with the outdoor temperature and selects the best energy-saving operation mode.

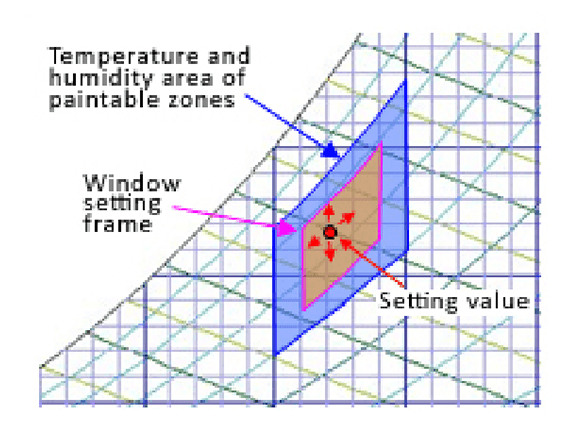

With the window control function, it performs control operations based on effective use of an allowed temperature and humidity control range.

Moreover, our solution flexibly handles a broad range of control modes including the use of temperature and relative humidity with solvent paints or the use of saturation with water-based paints.

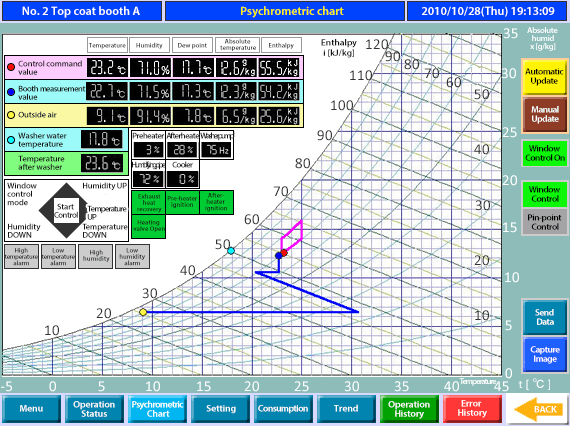

Screenshot of the control system (1)

Screenshot of the control system (1)

Screenshot of the control system (2)

Screenshot of the control system (2)

Features

In the past, the temperature and humidity of paint booths were controlled with three types of settings, depending on the season, or in some cases, the same setting was used all year round, consuming large amounts of energy for air conditioning.

But with the increasing focus on saving energy, the idea of operating paint booths within a certain range of tolerance began to spread.

Taking this situation into account, we provide systems that automatically calculate the optimal energy-saving settings within a fixed range of tolerance.

These energy-saving controls reduce CO2 (consumed energy converted to amount of CO2 emissions) by close to 20%, according to our independent calculations.