Iron Particle Removal System

Pre-treatment System | Work-clean technology

What is Pre-treatment System?

Pre-treatment system remove dust and grease adhering to surfaces to be painted in the initial process, and form a chemical conversion coating for metal surfaces. They enhance adhesion properties of the item to be painted, and provide anti-corrosion properties to metal.

What is work-clean technology?

Dust and dirt defects are the biggest causes of painting defects, so the pre-treatment process must remove any dirt adhering to the work. Taikisha provides several work-clean technologies, including the high-pressure washing system I-LAS.

- Want to lift productivity

Overview

Our pre-treatment system enables you to efficiently remove iron particle that is the cause of the defect.

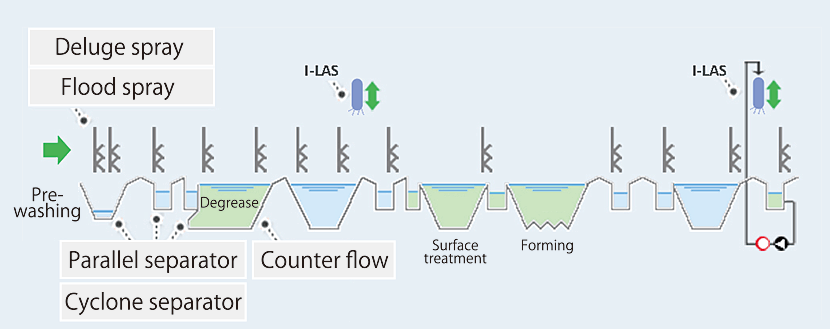

- Remove iron Particle from the body with the deluge spray and separate it with the parallel separator in the pre-washing process.

- Collect the iron Particle to the bottom of the entrance with the counter flow circulation in the degrease process.

- Use high-pressure spray (I-LAS) to wash off iron Particle from body surfaces in the water washing process.

System Image

System Image

Features

- There are steps for removing iron Particle from the body in every process, from the first process in the pre-treatment system (pre-washing flood spray) to the last process (I-LAS water washing after forming).

- The iron Particle removed from the body is collected by various separators and removed from the system. Parallel separator, cyclone separator, and other types of separators are available.