Pre-wash Microbubbles

Pre-treatment System | Grease-removal technology

What is Pre-treatment System?

Pre-treatment system remove dust and grease adhering to surfaces to be painted in the initial process, and form a chemical conversion coating for metal surfaces. They enhance adhesion properties of the item to be painted, and provide anti-corrosion properties to metal.

What is degreasing technology?

If grease is not thoroughly removed from the surface to be painted, the proper chemical conversion coating is not achieved, lowering anti-corrosion properties, and causing coating or other quality defects. Taikisha provides several technologies to improve grease removal, including use of micro-bubbles.

- Want to reduce CO2 and enhance energy efficiency

Overview

The use of microbubbles in the degreasing and cleaning process (pre-cleaning process) provides an efficient degreasing system. Microbubbles have a mechanism to improve degreasing performance. The pre-cleaning tank contains the surfactants contained within the degreasing solution, making it an ideal environment for the generation of microbubbles.

Features

-

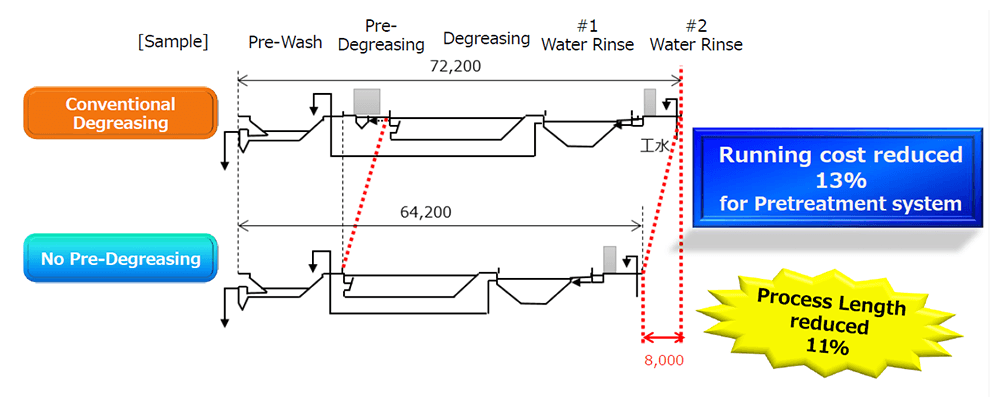

No preliminary degreasing

Microbubbles improve the degreasing performance in the pre-washing process, eliminating the need for preliminary degreasing.

-

*Patent pending

-

-

Low temperatures in the pre-washing tank

By introducing microbubbles into the pre-washing process, we can maintain the grease-removing performance while lowering the temperature in the pre-washing tank.

E.g. from 46°C to 35°C

Introduction Video

This video shows the degreasing effect of pre-washing microbubbles.