Odret (Direct Fired Incinerator)

VOC Removal Technology | Post-Processing Units

What is VOC removal technology?

We offer a wide variety of environmental protection devices, covers from various exhaust gas treatment systems and dust collectors to wastewater treatment systems. This section introduces exhaust gas treatment system to dispose organic gases from various plants.

What is post-processing units?

- Energy-saving technology that stores and reuses combustion heat waste in combustion type detoxification treatment for hazardous substances.

- Technology that can offer optimal incineration detoxifying treatment method for hazardous substances according to the exhaust conditions and treatment goals.

- Want to prevent air pollution

Overview

Odret was built on our vast experience as a paint plant manufacturer, and hundreds of these facilities are now in operation around the world.

It can handle gases with any component and concentration, and oxidize and decompose almost every harmful or malodorous component with a high treatment efficiency and consistency.

External view 1

External view 1

External view 2

External view 2

Internal view

Internal view

Exhaust gas treatment with Odret

- Uniformly heats a harmful or malodorous gas at 750°C or higher.

- Occurs when a target gas remains in the reactor for 0.5 seconds or longer.

In general, when treating an exhaust gas from the production process with only its oxidative decomposition energy for combustion, the concentration of the gas is not high enough to maintain the necessary temperature level in the reactor (750°C ). Therefore, some fuel is required, however its cost is saved with the heat exchange between an oxidized and decomposed gas and the next untreated gas (heat transfer efficiency = 75% max.)

Features

-

Consistent treatment

Treatment temperature can be easily adjusted based on the components in the exhaust gas, enabling consistent treatments. The exhaust gas components are fully treated with combustion.

-

High deodorization efficiency

Malodorous components are directly burned, decomposing and removing foul odors completely.

The exhaust gases containing silicon (Si), phosphorus (P), and sulfur (S), as well as gases containing tar, dust, mist, and metal vapors (Sn, Pb, and Hg) can also be treated. -

Economic efficiency with utilization of waste heat

When heat is required for purposes other than pre-heating untreated gases, two heat exchangers are installed, one for heating untreated gases and the other for transferring extracted heat. For this application, heat exchangers with various heat recovery rates can be paired.

-

Easy to maintain

Odret can easily be operated in full-automatic mode. Replacement of the catalyst is not required.

-

Optimal burner

The most appropriate burners are selected based on our vast experience and technologies. City gas, LPG, and lamp oil can be used as fuel.

Specifications

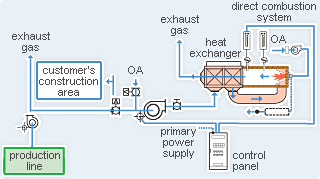

Flow diagram

Odret has a heating burner, reactor, and a heat exchanger to internally recover combustion energy.

Adaptive Industrial Sector

| Applicable Industry | Typical Target Substance |

|---|---|

| Paint factory | Toluene, xylene, IPA, methanol, MEK, and ethyl acetate |

| Printing factory | Toluene, IPA, MEK, hexane, ethyl acetate, aldehydes, ketones, ethylene, styrene, and acrylic acid |

| Chemical factory | Aldehydes, ketones, ethylene, styrene, and acrylic acid |

| Electric wire factory | Benzene, toluene, ester acetate, and phenol |

| Metal-casting factory | Phenol and formaldehyde |

| Food factory | Fatty acids, alcohols, amines, and hydrogen sulfide |

| Livestock and fishery processing Industries | Fatty acids and mercaptans |

| Rubber processing industry | Toluene, isocyanates, and the smell of rubber |

Dimensions of Standard Models

| Model | Treated Gas Volume(N㎥) | Required Heat(kcal/h) | Dimensions (mm) Length x Width x Height |

|---|---|---|---|

| OL-30 | 30 | 270,000 | 4,500×1,300×1,250 |

| OL-50 | 50 | 45,000 | 5,000×1,500×1,350 |

| OL-75 | 75 | 700,000 | 5,600×1,500×1,450 |

| OL-100 | 100 | 900,000 | 6,700×1,650×1,600 |

| OL-150 | 150 | 1,350,000 | 6,900×1,800×1,700 |

| OL-200 | 200 | 1,800,000 | 7,800×1,900×1,900 |

| OL-300 | 300 | 2,700,000 | 8,500×2,100×2,200 |