i-Sanding

Robot System Integrate | Automatic Sanding Solutions

What is robot system integration?

Simply collecting together robots, peripheral equipment, and tools does not result in the automation you might expect. Taikisha acts as a robotics system integrator to analyze specific issues for our users, so that we can provide the optimal systems and equipment.

What is automatic sanding solutions?

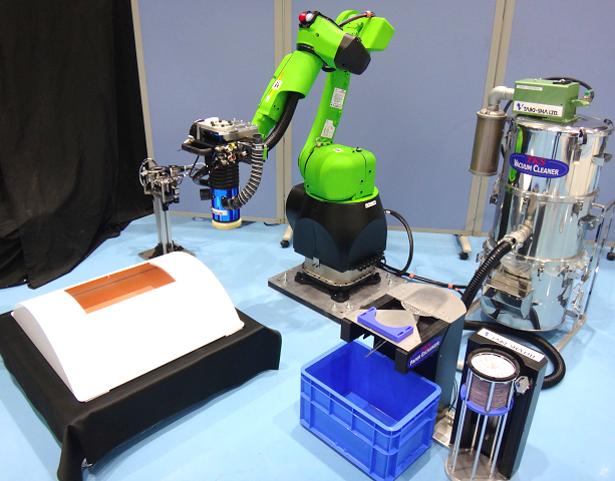

Taikisha provides sanding systems for coated surfaces that incorporate robots in the sanding tools to attain an even sanding force. Incorporating systems to detect the sanding load is a key feature. We have also prepared auxiliary equipment such as dust collectors for sanding machines and automatic abrasive removing devices.

- Want to lift productivity

- Want to heighten equipment efficiency and paint quality

- Want to improve labor environments and achieve automation

Overview

i-Sanding (automatic sanding system) is a high-speed, high-quality, sanding system. It has high-speed sensing in real time for feedback control of the force and position of the tool and the sanding load.

Exterior photo of i-Sanding configuration

Exterior photo of i-Sanding configuration

-

*Patent pending

Features

-

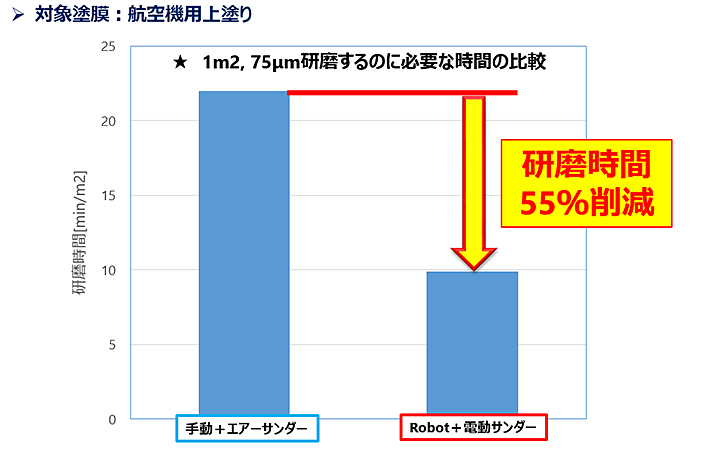

Reduction of sanding times

The robot can apply a powerful force when sanding, can reduce the time required.

If a motorized sander is used, the high torque can even further reduce the sanding time.

-

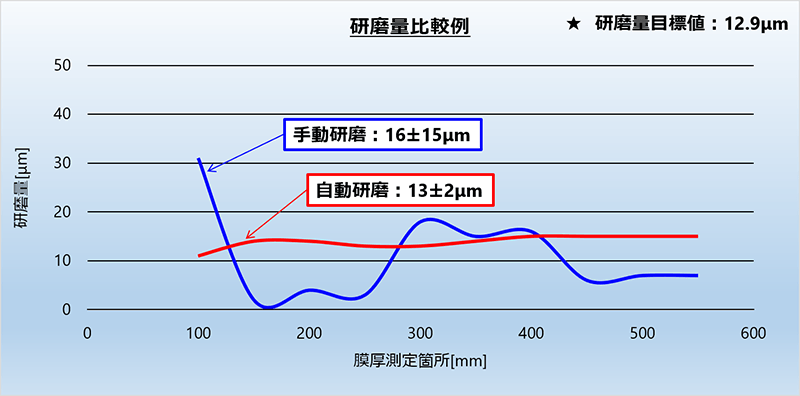

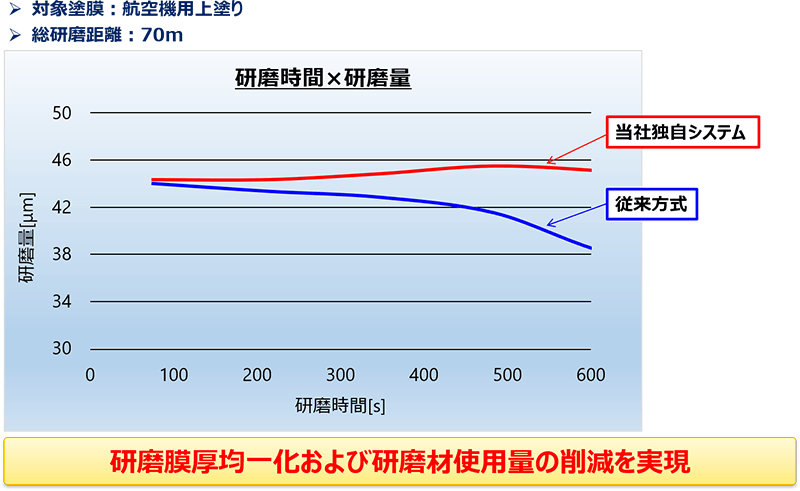

Thickness of the sanded coat and reduction of the amount of abrasives used

The automatic sanding system has high-speed sensing in real time for feedback control of the force of and position of the tool and the sanding load. So it can provide stable, high-quality sanding whatever the orientation.

Sanding with a consistent volume maximizes use of abrasives compared to manual work (the traditional method), so the time before replacement is required and the number of sheet used is reduced.

-

※Patent pending

-

-

Enhancement of the working environment

Dust collectors capture the abrasive powder generated during sanding. Collecting dust at the same time as the sanding prevents diffusion of abrasive powder to the surrounding area. This improves the working environment. It comes with a filter backwash pulse air mechanism that can maintain suction for a long time without becoming clogged. The filters can be washed in water for easy maintenance.