Efforts for Realizing a Low Carbon Society

Green Technology System Division

Taikisha is helping to reduce GHG emissions at the operation phase of the air-conditioning and sanitary facilities it provides to clients.

Toward the Targets of the Medium-Term and Long-Term Plans

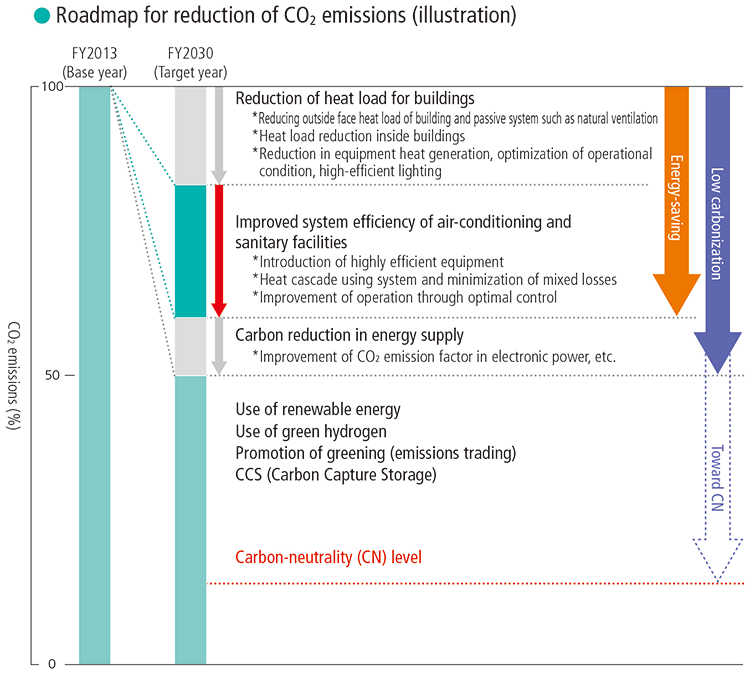

The Green Technology System Business aims to reduce the CO2 emission factor during the operation stage of projects designed and constructed by us by 25% by FY2030, compared with FY2013. We are promoting CO2 emissions reduction by proactively proposing both our existing energy saving technologies and those currently under development to ourcustomers.

We believe that drastic measures are required to realize carbon neutrality by 2050. In addition to reducing air conditioning loads and utilizing electricity from renewable energy sources, we are working on the development of CO2 separation and capture technologies, as well as technologies for energy transition to hydrogen, etc.

In July 2024, we began operations at the TAIKISHA INNOVATION SITE AIkawa, renewing the Research and Development Center located in Aikawa-cho, Aiko-gun, Kanagawa Prefecture. We will promote research and development, validation experiments, and simulations that contribute to carbon reduction.

Development of new room pressure control system

Taikisha will develop a new room pressure control system that enables reduction of air-conditioning conveyance power in pharmaceutical manufacturing plants, contributing to reduction of air-conditioning energy and running costs during non-work mode operation along with reduction of CO2 emissions.

Development of CO2 separation and utilization technology

While we are working to achieve carbon neutrality by 2050 through such means as energy saving and the use of facilities with low environmental impact, it is essential to introduce CCU (Carbon dioxide Capture and Utilization), a technology for CO2 separation and utilization, for areas where decarbonization is not viable. As such, Taikisha is developing DAC (Direct Air Capture) targeting CO2 in the atmosphere, utilizing adsorption and desorption technology to develop a CO2 concentration capture and supply system.

Eco-Friendly Design

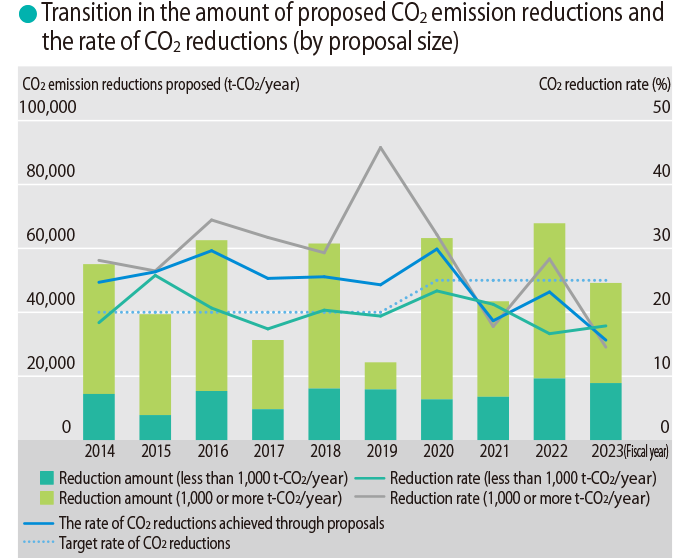

The Green Technology System Division, as part of promoting eco-friendly designs, makes proposals for improving the energy efficiency (reducing environmental impacts) of facilities owned by clients. In energy-saving proposal activities, the Division repeats the cycle of energy-saving diagnosis to grasp the current status, make detailed proposals based on clients’ future visions, design and installation based on energy-saving proposals, and verify the effects in the operation phase.

To contribute to the target reduction in GHG emissions by FY2030 (46.0% reduction compared with FY2013) under the Plan for Global Warming Countermeasures, an additional Cabinet decision made in October 2021, Taikisha has developed a proprietary simulation-based

Energy Plant Optimal Control System, which maximizes the reduction amount of energy saved by heat source systems through optimal operation control according to external conditions that change from hour to hour and thus helps reduce CO2 emissions and running costs.

- Target

- The CO2 reduction rate for in-house design projects (the reduction rate of CO2 emissions from customer-owned facilities enabled by our proposals): 25.0% or more on a weighted average

- Result

- 15.6%

Paint Finishing System Division

Taikisha is helping to reduce GHG emissions in the paint finishing process for automobiles, etc.

Toward the Targets of the Medium-Term and Long-Term Plans

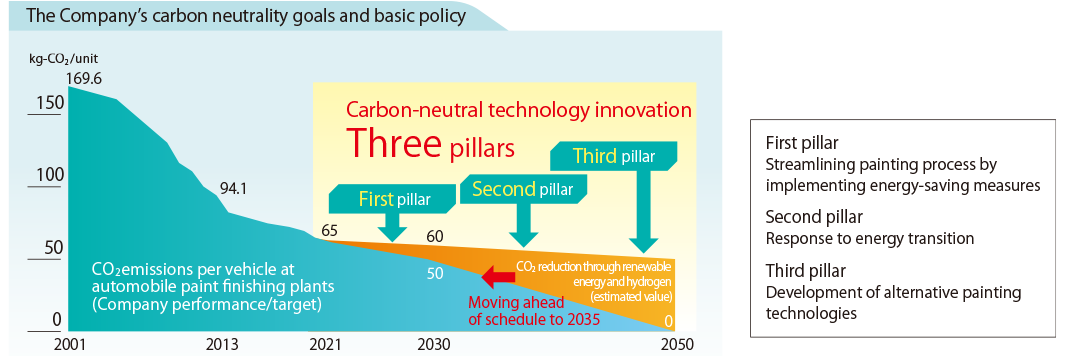

The Paint Finishing System Business aims to achieve 40.0 kg-CO2/unit by 2030, estimating CO2 emissions per unit of automobile painted, based on the energy estimation model for automobile paint finishing lines. Toward the realization of carbon neutrality in automobile painting processes, we are advancing technology development in collaboration with customers from various automobile manufacturers, having established three pillars of technological innovation.

To provide our developed technologies to ustomers in a timely manner, we are strengthening global collaboration and utilizing Computer Aided Engineering (CAE) from an efficiency standpoint.

Achievements of the Company’s Carbon Neutrality Initiatives and Future Targets

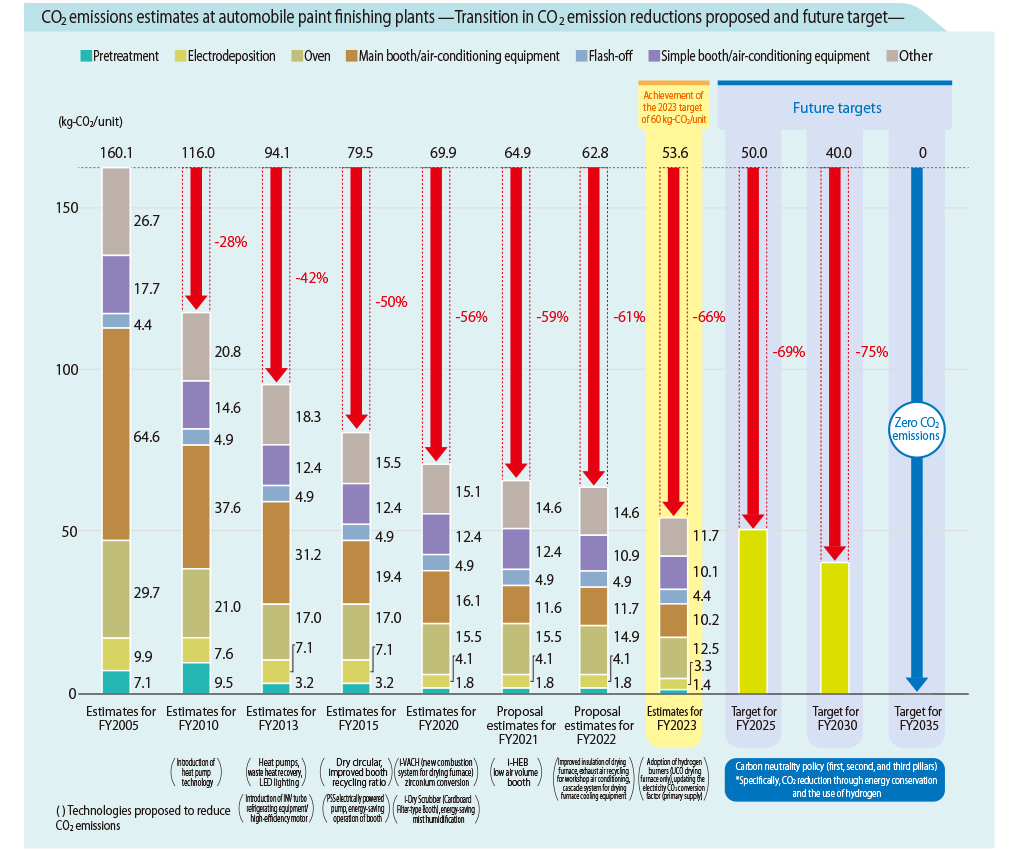

In order to visualize the CO2 emission reduction effects by the technologies we have proposed, we have been calculating and objectively evaluating CO2 emissions in automobile paint per unit since 2000, based on the energy estimation model for automobile paint finishing lines.

CO2 emissions in the 2005 model were estimated at 160.1kg-CO2 / unit, and we have since made various technology proposals to help reduce CO2, including the introduction of heat pump technology and high-efficiency equipment, and dry-type paint booths. Since 2020, we have proposed the development and improvement of low air volume booths, and indirect furnaces with VOC treatment functions, as products in line with the first pillar of our technology innovation. In recent years, we have been promoting further CO2 emission reductions by utilizing AI technology in production visualization systems and production analysis systems.

As a result of these initiatives, the FY2023 model achieved 60kg-CO2 / unit. Moving forward, we will promote initiatives along the three pillars, including the use of electricity from renewable energy sources in painting facilities (all-electric facilities), the use of hydrogen energy, and technological proposals for film decorating systems.

Additionally, while our previous goal was to achieve net zero CO2 emissions by 2050, we have moved the target date forward and now aim to achieve net zero CO2 emissions by 2035. The conditions necessary to achieve net zero by 2035 include the transition to renewable energy sources for power supply.

Looking back from the 2035 target, we have set interim goals of achieving 50kg-CO2 / unit by 2025 and 40kg-CO2 / unit by 2030.