Industrial HVAC Systems

HVAC system is essential not only for our daily lives, but also for the front lines of manufacturing. Taikisha designs and constructs HVAC systems to create optimal environments for manufacturing in factories and R&D facilities for many sectors, including electric and electronic components, chemical products, medical products, food, and printing.

Our strength in this field has a firm historical footing. As Japan's textile industry expanded in the 1930s, Taikisha worked on many large spinning mills, building up experience and pursuing the latest technologies to eventually expand in the 1960s to the HVAC system for synthetic fiber factories that demanded a high level of technology. Taikisha's name became synonymous with industrial HVAC from this time. Since then, as factory construction expanded from textiles to cameras, film, medical products, electronics, and other fields, Taikisha has refined its technological expertise in precision HVAC and cleanroom system to meet the need for equipment that can maintain a high level of cleanliness to prevent defects in products.

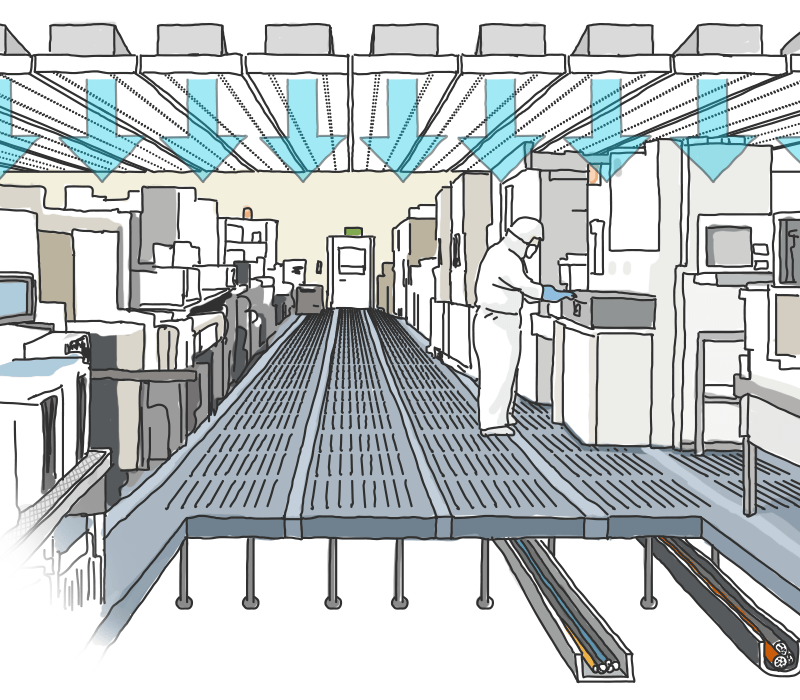

To meet the absolute requirements in manufacturing front lines for product quality, effectiveness, and safety, it is essential to maintain a set level of cleanliness, strictly controlling not just the temperature and humidity, but also particles and microorganisms in the air.

In the medical products field, for example, various measures are taken to maintain the cleanliness specified for each manufacturing process, and also advanced room-pressure control technology to control the flow of air is used to prevent cross contamination through reverse pressure between manufacturing rooms and areas. In the electric and electronic components field as well, particles adhering to products have an impact on quality and production efficiency, so their entry is prevented to heighten the yield rate (the actual production volume obtained compared to the amount of raw materials used).

Yet for cleanrooms, where these strict conditions are essential, making a large volume of air circulate results in huge amounts of electricity being consumed. Taikisha's solution to this is to use our unique environmental impact reduction technologies to optimally control the energy, conserving it while ensuring clean environments.

Leveraging our long years of experience in paint finishing system for automobiles, we have developed exhaust treatment systems to neutralize volatile organic compounds (VOCs). VOCs are widely used as solvents in manufacturing processes such as for automobile paint finishing system and printing, there are risks of causing air pollution and affecting the surronuding environment with malodorous odors, and affecting the health of factory workers. Installing exhaust treatment systems to neutralize VOCs generated in factories, so that only clean air is released, can greatly contribute to the prevention of air pollution. In recent years we are receiving more and more inquiries from China, which is increasingly tightening its environmental regulations, and other countries as well. Taikisha is working to attain further energy conservation in our exhaust treatment systems.

| Facility usage | Factories manufacturing electrical/electronic machinery; food and fishery factories; printing, publishing, and paper-making factories; factories manufacturing automobiles, railway vehicles, and aircraft; chemical, pharmaceutical, and textile factories |

|---|