Paint Finishing Systems

Taikisha designs and constructs automotive paint finishing system, leveraging our core technologies such as exhaust treatment and airflow controls developed in our industrial HVAC business. We have a long history of working in this business, going all the way back to the 1960s. Today our automotive paint finishing system, harmonizing a high paint quality with environmental impact reduction technologies, attain large sales in the global market and are introduced by automotive manufacturers not just in Japan, but all around the world.

A beautiful finish to painting requires to maintain the optimal temperature and humidity as well as a high level of cleanliness to shut out even tiny dust particles, which is why cleanroom technology is used in automotive paint booths. Airflow controlling is also absolutely essential to quickly remove the paint mist that fails to adhere to the car body during the painting process without being diffused.

At the same time, pursuing energy conservation and environmental impact reduction is the biggest theme because much energy is required for air conditioning when painting something as large as an automobile.

Taikisha leverages many different environmental technologies, such as saving energy by suppressing airflow in the booth and temperature in the drying oven, saving electricity by reusing the heat of high-temperature exhaust gases and by advancing electrodeposition tanks, and furthermore reducing harmful VOCs by improving paint coating efficiency, to meet the needs of our customers and satisfy the demands of society.

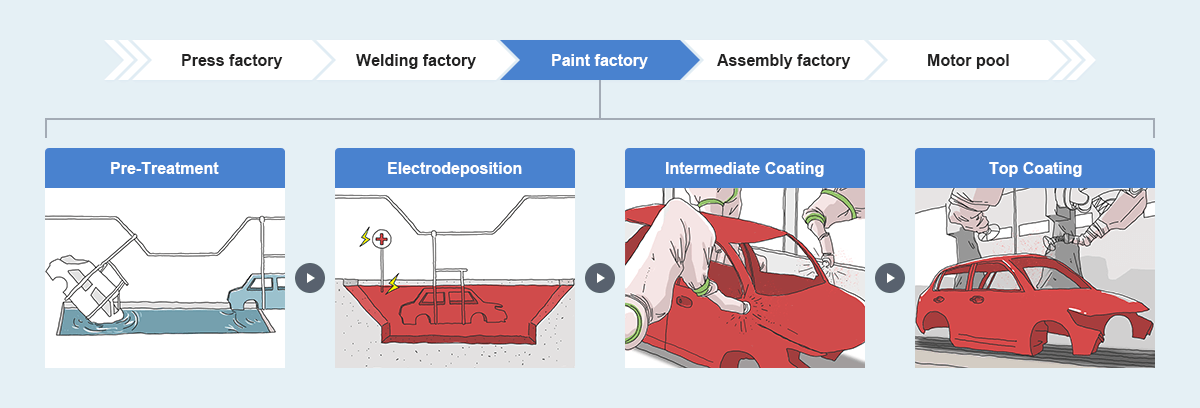

Automotive paint finishing requires several coats in order to achieve a beautiful finish. The following describes the flow of the painting process.

-

Pre-Treatment

Prior to painting, we remove any iron powder and other dust from the surface of the car body, as these are the main causes of paint defects, and also apply special surface treatment with chemicals to improve paint adhesion.

-

Electrodeposition

Anticorrosive paint is applied as the undercoating to prevent rust on the car body.

Dipping the body and applying a direct current in an Electro-deposition tank enable to make the coating thickness uniform with short time.

After this process, the body is placed in a drying oven to dry the paint to form a coating film. -

Intermediate Coating

Paint is applied in this process to make the color of the car body appear even more beautiful.

After painting, the body is again placed in a drying oven to dry the paint to form a coating film. -

Top Coating

This painting process is to express the color of the car body after electrodeposition and intermediate coating.

As with the intermediate coating, the body is placed in a drying oven to dry the paint to form a coating film after painting.

In recent years, Taikisha is utilizing our technologies developed in automotive paint finishing to paint aircraft and railway vehicles.