TAIKISHA (THAILAND) CO.,LTD TECHNICAL CENTER ASEAN

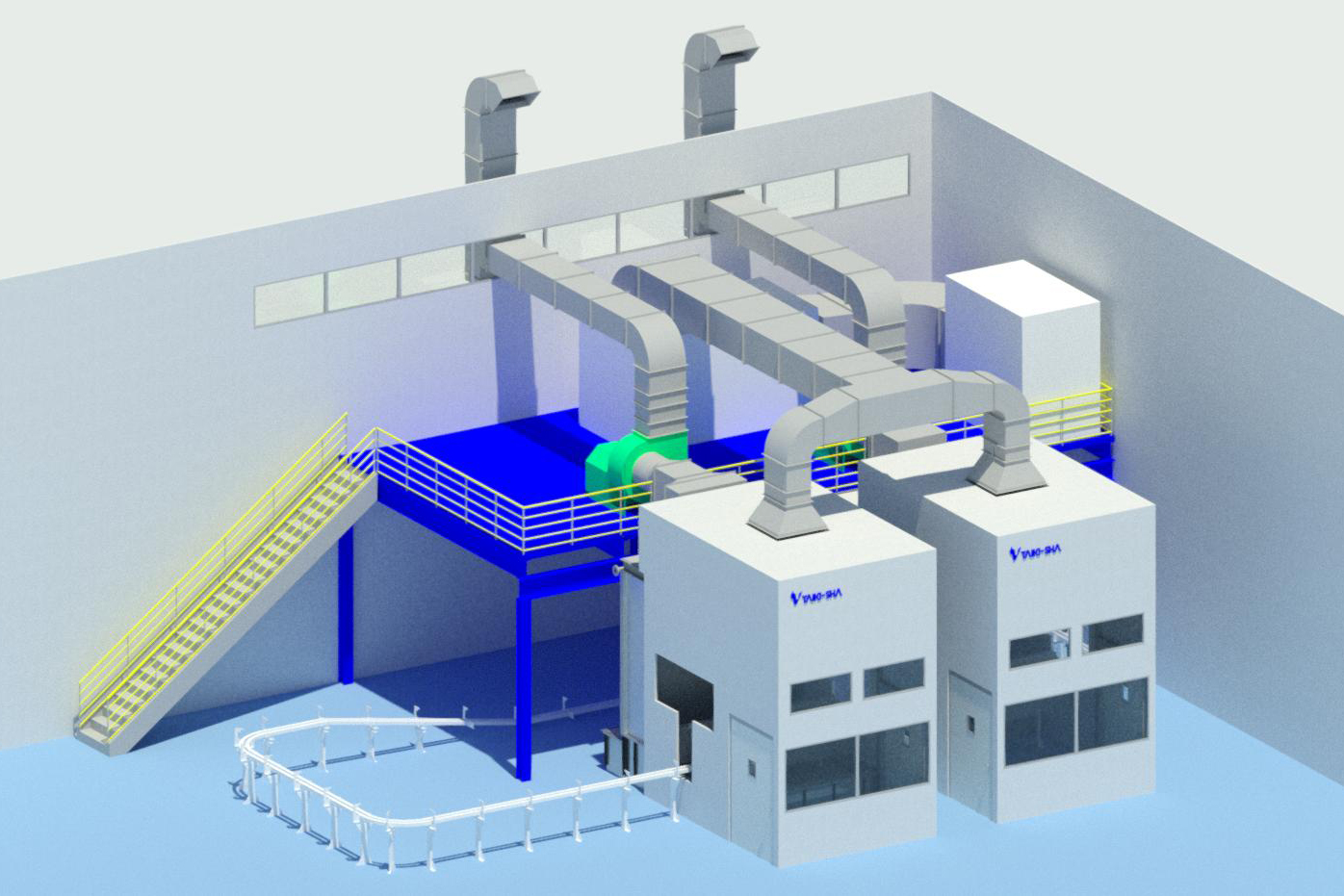

Overview of the facility

It is located on the premises of our Bangplee can manufacturing factory and consists of a painting area and an office.

Facility information

Painting area

To deal with various products requiring painting and respond to various conditions, the conveyor in front of the booth is equipped with a continuous rotating mechanism, an index rotating mechanism, etc., which make it possible to perform a wide range of painting tests.

By using the state-of-the-art robots of Japan's two largest robot manufacturers installed therein, and bells and air guns of the manufacturers that Taikisha Japan also deals with, it is possible to conduct painting tests that reproduce the environment of the actual production line, and to check the capability of the paint finishing system and the quality of paint films before an equipment introduction plan or the delivery of equipment to the site.

In addition, owing to the below listed equipment and devices installed in the painting area, this area can also be used for a site competent for verifying new painting processes.

- Painting devices (bell, air gun)

- Painting robots (two robots)

- Paint supply devices (gear pump, CCV, etc.)

- Painting booths (two booths)

- Baking and drying oven (batch type)

- Chain type continuous conveyor (equipped with a rotating mechanism in front of the booth)

Can manufacturing plant area

On the same premises, there is a can manufacturing plant and it can also produce jigs, etc. to be used for tests.