Health & Safety Management

- Value Creation Foundation for Safety

- Health & Safety Policy

- Health & Safety Management System

- Health & Safety Management Activities

- Efforts for Accident Prevention

- Efforts for Improvement of Industrial Health & Safety Management in Overseas Affiliates

- Development of Human Resources for Industrial Safety and Health

Value Creation Foundation for Safety

Basic Safety Philosophy

Based on our Corporate Philosophy of contributing to society and establishing an attractive company, and guided by our Safety Management Vision and the guidelines for its realization, we promote activities that prioritize safety and create safe and comfortable working environments for everyone involved with the company.

Safety Management Vision

Based on an understanding of the importance of human life as a basic principle, we thoroughly implement safety-first planning and construction and fulfill our social responsibilities in our corporate activities out of respect for the law. Aiming to protect the health and lives of workers and create more comfortable working environments, we will establish a management foundation on which we can conduct reliable and sustainable corporate activities through our contributions to society.

Guidelines for the realization of Taikisha’s Safety Management Vision

- Prevent critical and public disasters.

- Develop comfortable working environments.

- Improve the level of health and safety management in the Taikisha Group.

- Promote prevention activities with safety plans and procedures that emphasize foolproof and fail-safe practices.

Health & Safety Policy

Green Technology System Division

- Basic Philosophy

- We at the Green Technology System Division will thoroughly plan and implement operations based on a policy of safety first, protecting the lives and health of workers, incorporating legal compliance processes into our safety measures, and striving to improve the work environment. Furthermore, we will build a firm management foundation by implementing sustainable, trusted corporate activities through contribution to society.

Paint Finishing System Division

- Basic Philosophy

- We at the Paint Finishing System Division, in response to the Basic Philosophy, Safety Management Vision, and Realization Guidelines set forth in the company-wide safety-related value creation foundation, will work to establish and implement safety policies that focus on preventing serious and public accidents, creating a comfortable working environment for all, improving health and safety management standards, and emphasizing fool-proofing and fail-safe measures.

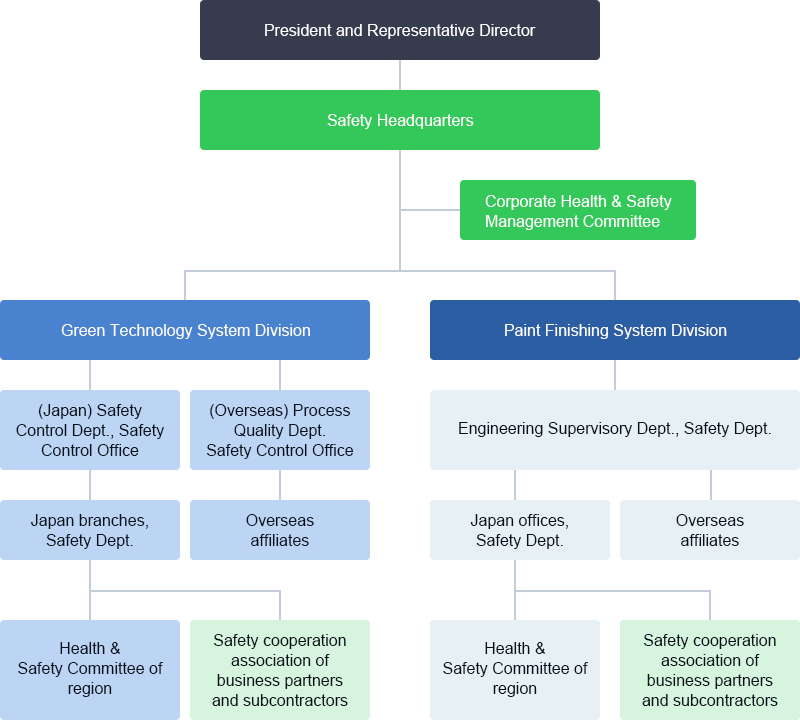

Health & Safety Management System

Health & Safety Management System Chart

We have established our own Taikisha Industrial Health and Safety Management System based on the basic principles of respect for human life and a spirit of compliance. We have established a Safety Headquarters at the headquarters and a safety management department in each division, and these are responsible for overall management as well as providing support for the safety activities of individual branches and offices.

Taikisha Group’s Status of Acquisition of ISO Certification

Asia

| Country Name | Company Name | ISO45001 |

|---|---|---|

| Japan | Taikisha Ltd. | *1 |

| Thailand | Taikisha (Thailand) Co., Ltd. | ○ |

| Greater China | WuZhou Taikisha Engineering Co., Ltd. | ○ |

| Greater China | Tianjin Taikisha Paint Finishing System Ltd. | ○ |

| Philippines | Taikisha Philippines Inc. | ○ |

| Vietnam | Taikisha Vietnam Engineering Inc. | ○ |

| India | Taikisha Engineering India Private Ltd. | ○ |

| India | Nicomac Taikisha Clean Rooms Private Limited | *3 Acquisition scheduled for 2026 |

| Indonesia | P.T. Taikisha Indonesia Engineering | ○ |

| Singapore | Taikisha (Singapore) Pte. Ltd. | ○ |

| Malaysia | Taikisha Engineering (M) Sdn. Bhd. | ○ |

| Cambodia | Taikisha (Cambodia) Co.,Ltd. | *4 |

| Lao | Taikisha Lao Co., Ltd. | *4 |

| South Korea | Taikisha Korea Ltd. | *1 |

| Taiwan | Taikisha (Taiwan) Ltd. | *2 Acquisition scheduled for 2026 |

North America

| Country Name | Company Name | ISO45001 |

|---|---|---|

| USA | Taikisha USA, Inc. | *5 |

South America

| Country Name | Company Name | ISO45001 |

|---|---|---|

| Brasil | Taikisha do Brasil Ltda. | ○ |

Europe

| Country Name | Company Name | ISO45001 |

|---|---|---|

| Germany | Taikisha Deutschland GmbH | *1 Acquisition scheduled for 2026 |

-

*1Currently operating own in-house system compliant with Japan's Construction Occupational Health and Safety Management System (COHSMS)

-

*2Currently operating own in-house system compliant with OHSAS 18001

-

*3Currently operating under IS 18001:2007

-

*4Comply with the management system of the branch in charge of each property

-

*5Currently operating own in-house system compliant with Occupational Health and Safety Assessment Series (OHSAS)

Health & Safety Management System and Activities

Taikisha measures and monitors the effects of safety activities by using a frequency rate that indicates the frequency of industrial accidents and a severity rate that indicates the severity of accidents as safety indicators. The transition of these indicators is as follows.

- Frequency rate: This indicates the frequency of occurrence of industrial accidents, which is calculated based on the number of deaths and injuries due to industrial accidents (accidents involving at least four days of lost work time according to the criteria of the Ministry of Health, Labour and Welfare) per 1,000,000 cumulative hours worked.

- Severity rate: This indicates the degree of seriousness of the accident, which is calculated based on the number of work-days lost per 1,000 cumulative hours worked.

- Scope: Taikisha's construction sites (employees on a non-consolidated basis and subcontractors)

Frequency and Severity Rate Indicators for the Past Five Years in Japan

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Frequency rate | 0.536 | 0.411 | 0.12 | 0.42 | 0.69 |

| Severity rate | 0.010 | 0.022 | 0.001 | 0.043 | 0.050 |

Number of Industrial Accidents Occurred

unit: Cases

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Fatal/serious industrial accidents | 0 | 0 | 0 | 0 | 0 |

| Industrial accidents involving at least four days of lost work time | 4 | 3 | 1 | 4 | 5 |

Efforts for Accident Prevention

Taikisha created the videos of past accident cases, including crashes and falls, and have begun viewing them to prevent similar accidents. We plan to expand these videos to our overseas offices in the future.

Efforts for Improvement of Industrial Health & Safety Management in Overseas Affiliates

Every two years, the Safety Headquarters conducts an audit of each overseas office and workplace to ensure that they are in compliance with occupational health and safety management activities based on each site's health and safety management system.

Conferences and Safety Training by Inviting Overseas Local Staff Members

On an annual basis, engineering and safety staff of overseas affiliates are assembled in Japan to be provided with safety education, in an effort to improve their safety management skills. In FY2024, we invited technical staff from overseas affiliates to Japan, and held a group safety training meeting for them.

Safety Education Items for Staff Members of Overseas Business Offices

- Accident prevention through risk assessment

- Analysis of accident causes

- Review of accident prevention measures and group presentations

- Domestic site inspections with safety patrols

Development of Human Resources for Industrial Safety and Health

Taikisha implements the following initiatives with the aim to develop safety staff in Japan and overseas.

Establishment of information-sharing website for all the safety staff

An information-sharing website was launched for all the safety staff including overseas staff. Safety information and manuals are available in Japanese, English and Chinese.

Staff training on safety

In FY 2024, we conducted five safety training sessions in Japan as part of level-based employee training (practical scaffolding planning training) for 523 site managers and deputy site managers. Additionally, we provided VR-based hazard awareness training for a total of 685 employees of Taikisha and business partners. We are also working to enhance safety awareness among 1,158 overseas staff through biannual e-learning programs and the distribution of safety-related emails four times a month. Starting in FY 2025, we plan to roll out the VR-based hazard awareness training at our overseas subsidiaries. We will continue to provide education and information to overseas staff through e-learning as well as by distributing videos based on actual accident cases from our sites in Japan and overseas.

Implementation of general training including safety

The Company set a rule that requires each office, etc. to provide education to its staff and partners about the systems and other matters in accordance with the “education manual for employee preparatory training, business partner training, staff preparatory training and site staff training,” and planned or conducted about 15 different safety trainings at various offices including Safety Headquarters. The Safety Headquarters also conducts training for new staff and new managers as well as various other level-specific training sessions once a year.