Automobile Factory / Railway Factory / Aircraft Factory

Search for Technologies and Services

Search for Technologies and Services

- Search by Solution

-

-

results0

0results

-

VOC Removal TechnologyConcentrating Units

Admat®C/Admat®Z

This system cleans up organic solvents, cleaning solvents, and malodorous gases, using adsorbing materials and oxidative decomposition equipment. Fibrous activated charcoal and hydropholic sysntheic zeolite are used as the adsorbing materials.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

-

VOC Removal TechnologyPost-Processing Units

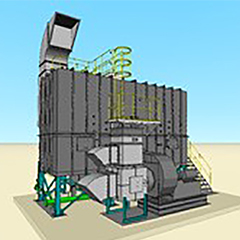

RTO (Regenerative Thermal Oxidizer)

RTO(Regenerative Thermal Oxidizer) is energy-saving system that oxidizes and decomposes VOCs (Volatile Organic Compounds) at 850℃ or higher. It is suitable for the treatment of high concentration gases and for use as a post-treatment unit to Admat.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

-

VOC Removal Technology

Rotary RTO/Horizontal Rotary RTO

Rotary RTO includes a regenerative heat exchanger with rotary changeover valves. Horizontal Rotary RTO is new type of RTO with significantly reduced unit height by having a switching valve installed on the side of the conventional RTO main unit.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

-

VOC Removal TechnologyPost-Processing Units

Cataburn® (Catalytic Burning VOC Abatement System)

Cataburn® has an especially great effect on the treatment of difficult-to-reuse mixed solvent gases and malodorous gases. It can also be effectively used as post-treatment system to Admat®C/Admat®Z.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

-

VOC Removal TechnologyPost-Processing Units

Odret (Direct Fired Incinerator)

Odret can handle gases with any component and concentration, and oxidize and decompose almost every harmful or malodorous component with a high treatment efficiency and consistency.

- Want to prevent air pollution

-

Acoustic Control Technology

Path Difference Silencer

This silencing system focuses on the fact that sound comes in waves, and splits the original sound into two paths with differing lengths to reduce noise through superimposition with the confluent section.

- Want to lower noise levels

-

Acoustic Control Technology

Resonant-type Silencer

The resonant-type silencer is a sound dampening system that alters the phases of sound and then synthesizes them to utilize their property of mutually canceling each other.

- Want to lower noise levels

-

Acoustic Control Technology

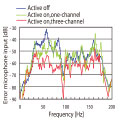

Active Noise Control

Active Noise Control measures sound defected in paths and applies a reverse-phase sound to cancel.

- Want to lower noise levels

-

Acoustic Control Technology

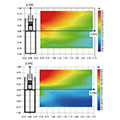

Noise Control for Air Conditioner Outdoor Units

By examining the off-site noise generated by outdoor units, Taikisha designs optimal sound-reducing systems (in terms of cost and pressure loss) to meet the performance requirements.

- Want to lower noise levels

-

Acoustic Control Technology

Outdoor Unit Countermeasures via Edge-effect Suppression Theory

Taikisha concluded an agreement with Kansai University to implement noise barriers applying the edge-effect suppression theory. Based on these principles, we developed a soundproofing system for air conditioner outdoor units.

- Want to lower noise levels

-

Centrifugal Water Separation Technology

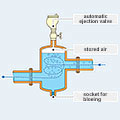

Aquavent · mark II (Prevention of Air Lock, Noise, and Corrosion)

Aquavent・markⅡ resolves faults caused by air mixed into piping.

- Want to enhance safety and reliability

-

Heat Source Equipment Control Technology/Optimal Operation Technology

Optimum Heat Source Control System

Heat source optimal control system maximizes the impact of energy saving for the entire system with optimized real-time setting values.

- Want to reduce CO2 and enhance energy efficiency

-

Low Wind Speed Cooling Technology

Sock Chilling System (Cloth Filter)

Sock chilling system creates uniform indoor airflows by passing the air through a cloth filter.

- Want to build comfortable spaces

-

High-Speed Moisture Capture Technology

Louvreme® (Vertical-type Waterproof Louver)

Taikisha provides louvers that drastically improve the effectiveness of design, functionality, and earthquake resistance.

- Want to make the best use of limited spaces

-

Heat Storage Technology

Stratherm® System / Super Stratherm · G / Stratherm® · I

A heat storage tank is in the form of heat in an underground or aboveground water tank. It stores inexpensive night-time power, and utilizes it during the daytime, the peak hours of heat demand.

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

- Want to improve labor environments and achieve automation

-

Environmental Testing EquipmentEnvironment Reproduction Technology

Test Environment

This control technology uses a direct expansion system to further reduce environmental impact. This reproduces natural environmental conditions in test chambers with high accuracy.

- Want to reduce CO2 and enhance energy efficiency

- Want monitoring and control

- Want to make the best use of limited spaces

-

Environmental Testing EquipmentTemperature And Humidity Control Technology

Engine Intake System

This system supplies air to engines at a constant temperature and humidity during an engine unit test.

- Want to reduce CO2 and enhance energy efficiency

- Want monitoring and control

-

Environmental Testing EquipmentAirflow Control Technology

Wind Tunnel Technology

A wind tunnel is used to artificially generate wind. By measuring the aerodynamic characteristics in a wind tunnel, data for product development and design can be obtained.

- Want to reduce CO2 and enhance energy efficiency

- Want monitoring and control

-

Direct-Expansion Air Conditioning Technology

Direct Expansion HVAC

Taikisha has developed our direct-expansion HVAC that contains an inverter condensing unit and it is applicable to facilities where no central heating facility is equipped.

- Want to make the best use of limited spaces